Lubricant Component

Additives are synthetic chemicals which can either provide certain properties in lubricants or prevent unwanted conditions from occurring in the finished lubricants

Products Lubricant Component

-

Viscosity & Viscosity Inde...

Sever viscosity fluctuation resulted from temperature variation may impact negatively on the performance of lubricants.

View more details -

Pour Point Depressant

The pour point of a lubricant is the lowest temperature that a fluid can flow in standard conditions. Pour Point Depressants (PPD) are polymers that are significantly designed to control wax crysta...

View more details -

Silicon & Non Silicon Anti...

Foams in lubricants which are resulted from sever agitation of air with lubricant in industrial lubricating systems are often-unwanted phenomena which will leave negative impacts on functionality o...

View more details -

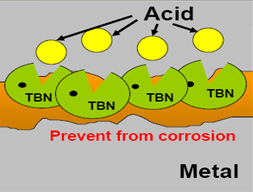

TBN Booster

Detergents play crucial role in protecting various metallic surfaces of components in internal combustion engines through neutralizing acidic complexes already formed during combustion processes. F...

View more details -

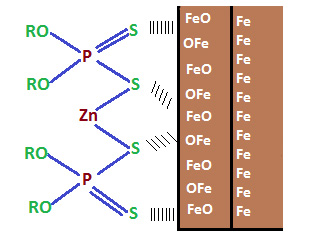

Anti Wear Additives

Anti Wear additives are multifunctional additives used in engine oils, transmission fluids, gear oils, hydraulic fluids, greases and etc. Zinc Dialkyl Dithiophosphate (ZDDP) additive is generally u...

View more details -

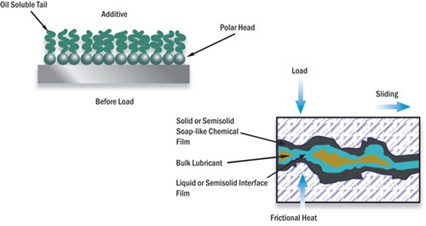

Extreme Pressure

EP additives are chemicals composed of sulfur and phosphorous that are used to protect metal-metal contact surface at high pressure and to provide lubricity to the interface layer. They provide con...

View more details -

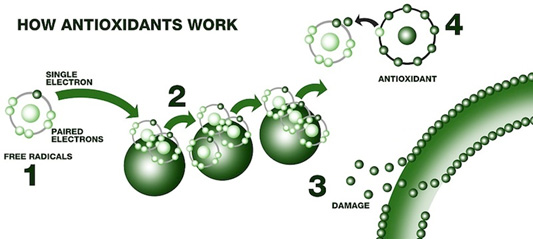

Antioxidant

Stability of lubricant against thermal stress is a key issue for the fact that oxygen and oxidation accelerating chemicals which develop decomposition of lubricants. Acids generated through oxidati...

View more details -

Tackiness Additives

This type of additive is served in application where oil spray or flow is not tolerated such as in electrical saw, open gear oil, drilling machine, sliding greasing system or looming machineries. T...

View more details -

Emulsifier & Demulsifier

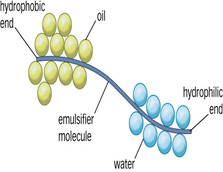

Emulsifier is a type of surfactant typically used to keep emulsion (mixture of immiscible fluids) well dispersed. Emulsifiers normally have a hydrophobic (water -hating) and a hydrophilic (water - ...

View more details -

Oil Soluble Dyes

Dyes are mainly added to lubricants in order to make them identified from other types of lubricants. For instance, the red dye is widely used in automatic gear oils however suppliers of lubricants ...

View more details -

Water Soluble Dye

Antifreezes are mixed with water soluble dyes selected from a wide range of colorful patterns such as yellow, green and green fluorescent in order to be distinguished by other fluids used in engine...

View more details -

Essence

Essence is used at a very small concentration as deodorants to base oils with unpleasant fragrances. The main application is in re-refined base oils.

View more details

Viscosity & Viscosity Index Improver

Product Code : 69

Sever viscosity fluctuation resulted from temperature variation may impact negatively on the performance of lubricants.

More detailsViscosity & Viscosity Index Improver

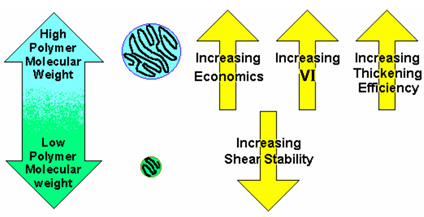

Product code: 69Sever viscosity fluctuation resulted from temperature variation may impact negatively on the performance of lubricants. To prevent this from happening and to increase the viscosity index, below types of polymers are used:

♦ Polymethacrylate (PMA)

♦ Olefin Copolymers (OCP)

♦ Polyisobutene (PIB)

♦ Hydrogenated Styrene-Isoprene (SIP) The selection of appropriate polymer is significantly important as each polymer may behave in a unique way in terms of viscosity, viscosity index and shear stability.

For further information please contact our company.

Pour Point Depressant

Product Code : 70

The pour point of a lubricant is the lowest temperature that a fluid can flow in standard conditions. Pour Point Depressants (PPD) are polymers that are significantly designed to control wax crystal formation in lubricants and to improve lubricant’s fluidity at low temperatures.

More detailsPour Point Depressant

Product code: 70The pour point of a lubricant is the lowest temperature that a fluid can flow in standard conditions. Pour Point Depressants (PPD) are polymers that are significantly designed to control wax crystal formation in lubricants and to improve lubricant’s fluidity at low temperatures.

For further information please contact our company.

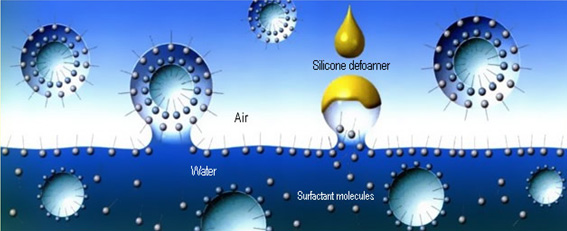

Silicon & Non Silicon Anti Foam

Product Code : 71

Foams in lubricants which are resulted from sever agitation of air with lubricant in industrial lubricating systems are often-unwanted phenomena which will leave negative impacts on functionality of lubricant and lubricating systems. Increasing oxidation rate in lubricants or pitting corrosion are just examples of destructive impact that could happen in absence of anti foams.

More detailsSilicon & Non Silicon Anti Foam

Product code: 71Foams in lubricants which are resulted from sever agitation of air with lubricant in industrial lubricating systems are often-unwanted phenomena which will leave negative impacts on functionality of lubricant and lubricating systems. Increasing oxidation rate in lubricants or pitting corrosion are just examples of destructive impact that could happen in absence of anti foams.

For further information please contact our company.

TBN Booster

Product Code : 72

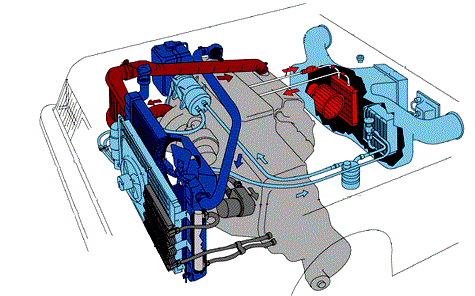

Detergents play crucial role in protecting various metallic surfaces of components in internal combustion engines through neutralizing acidic complexes already formed during combustion processes. For instance, in diesel engines, sulfuric and organic acids are produced through an oxidation process between sulfur (available in the fuel and lubricant) and oxygen.

More detailsTBN Booster

Product code: 72Detergents play crucial role in protecting various metallic surfaces of components in internal combustion engines through neutralizing acidic complexes already formed during combustion processes. For instance, in diesel engines, sulfuric and organic acids are produced through an oxidation process between sulfur (available in the fuel and lubricant) and oxygen. The Total Base Number (TBN) reflects the acid-neutralizing ability, scaled on mgKOH/g of additive. TBN Booster or high TBN overbased detergents reduce these complications with excellent detergency and rust inhibiting properties.

For further information please contact our company.

Anti Wear Additives

Product Code : 74

Anti Wear additives are multifunctional additives used in engine oils, transmission fluids, gear oils, hydraulic fluids, greases and etc. Zinc Dialkyl Dithiophosphate (ZDDP) additive is generally used for its excellent anti wear and extreme pressure (EP) specification with effective oxidation and corrosion inhibitor properties.

More detailsAnti Wear Additives

Product code: 74Anti Wear additives are multifunctional additives used in engine oils, transmission fluids, gear oils, hydraulic fluids, greases and etc. Zinc Dialkyl Dithiophosphate (ZDDP) additive is generally used for its excellent anti wear and extreme pressure (EP) specification with effective oxidation and corrosion inhibitor properties.

For further information please contact our company.

Extreme Pressure

Product Code : 75

EP additives are chemicals composed of sulfur and phosphorous that are used to protect metal-metal contact surface at high pressure and to provide lubricity to the interface layer. They provide conditions to avoid bonding of metal surfaces to each other and typically used in gear oil, cutting oil and grease.

More detailsExtreme Pressure

Product code: 75EP additives are chemicals composed of sulfur and phosphorous that are used to protect metal-metal contact surface at high pressure and to provide lubricity to the interface layer. They provide conditions to avoid bonding of metal surfaces to each other and typically used in gear oil, cutting oil and grease. For further information please contact our company.

Antioxidant

Product Code : 76

Stability of lubricant against thermal stress is a key issue for the fact that oxygen and oxidation accelerating chemicals which develop decomposition of lubricants. Acids generated through oxidation of lubricants may significantly increase the corrosion rate of metallic surfaces. Antioxidants, both aminic and phenolic types, prevent oxidation reaction from happening and will also enhance the life of lubricant. Aaminic antioxidants are highly recommended versus phenolic type at high temperature conditions.

More detailsAntioxidant

Product code: 76Stability of lubricant against thermal stress is a key issue for the fact that oxygen and oxidation accelerating chemicals which develop decomposition of lubricants. Acids generated through oxidation of lubricants may significantly increase the corrosion rate of metallic surfaces. Antioxidants, both aminic and phenolic types, prevent oxidation reaction from happening and will also enhance the life of lubricant. Aaminic antioxidants are highly recommended versus phenolic type at high temperature conditions. For further information please contact our company.

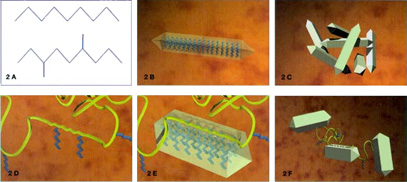

Tackiness Additives

Product Code : 77

This type of additive is served in application where oil spray or flow is not tolerated such as in electrical saw, open gear oil, drilling machine, sliding greasing system or looming machineries. The stability of lubricant film on engaged parts in different conditions which will also create an effective hydrodynamic lubrication system and corrosion protect is duly resulted from tackiness improving characteristic of this additive.

More detailsTackiness Additives

Product code: 77This type of additive is served in application where oil spray or flow is not tolerated such as in electrical saw, open gear oil, drilling machine, sliding greasing system or looming machineries. The stability of lubricant film on engaged parts in different conditions which will also create an effective hydrodynamic lubrication system and corrosion protect is duly resulted from tackiness improving characteristic of this additive.

For further information please contact our company.

Emulsifier & Demulsifier

Product Code : 78

Emulsifier is a type of surfactant typically used to keep emulsion (mixture of immiscible fluids) well dispersed. Emulsifiers normally have a hydrophobic (water -hating) and a hydrophilic (water - liking) end. The emulsifiers will surround an oil (or other immiscible molecule) and form protective layer so that the oil molecules can’t clump together.

More detailsEmulsifier & Demulsifier

Product code: 78Emulsifier

Emulsifier is a type of surfactant typically used to keep emulsion (mixture of immiscible fluids) well dispersed. Emulsifiers normally have a hydrophobic (water -hating) and a hydrophilic (water - liking) end. The emulsifiers will surround an oil (or other immiscible molecule) and form protective layer so that the oil molecules can’t clump together. This action helps keeps the dispersed phase in small droplets and preserves the emulsion.

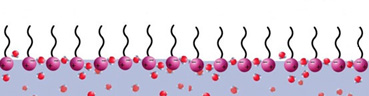

Demulsifier

Most of industrial oils in circulation systems require excellent demulsification properties in order to separate water contamination from the lubricating system. Without demulsifiers lubricating oils can form relatively stable water-in-oil emulsions.

Oil Soluble Dyes

Product Code : 79

Dyes are mainly added to lubricants in order to make them identified from other types of lubricants. For instance, the red dye is widely used in automatic gear oils however suppliers of lubricants may use certain dye for marketing purpose. It is worth noting that the color of lubes does not represent quality and in fact only specific quality measurements can reflect on the quality.

More detailsOil Soluble Dyes

Product code: 79Dyes are mainly added to lubricants in order to make them identified from other types of lubricants. For instance, the red dye is widely used in automatic gear oils however suppliers of lubricants may use certain dye for marketing purpose. It is worth noting that the color of lubes does not represent quality and in fact only specific quality measurements can reflect on the quality.

Water Soluble Dye

Product Code : 80

Antifreezes are mixed with water soluble dyes selected from a wide range of colorful patterns such as yellow, green and green fluorescent in order to be distinguished by other fluids used in engines.

More detailsWater Soluble Dye

Product code: 80Antifreezes are mixed with water soluble dyes selected from a wide range of colorful patterns such as yellow, green and green fluorescent in order to be distinguished by other fluids used in engines. For further information please contact our company.

Essence

Product Code : 81

Essence is used at a very small concentration as deodorants to base oils with unpleasant fragrances. The main application is in re-refined base oils.

More detailsEssence

Product code: 81Essence is used at a very small concentration as deodorants to base oils with unpleasant fragrances. The main application is in re-refined base oils.